The Mechanics of Shearography

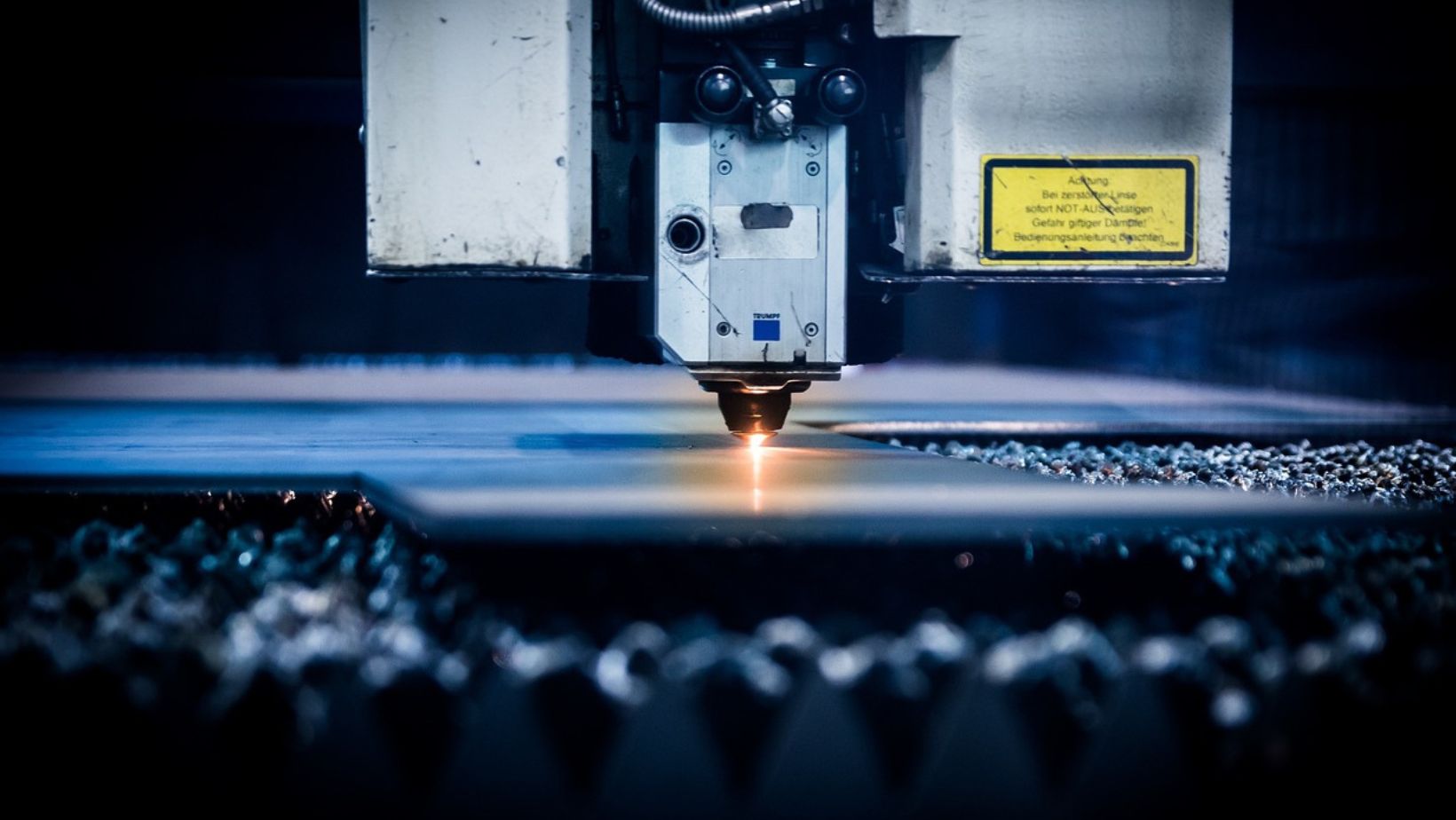

Shearography relies on the principle of laser diffraction and optical interference. At its core, a laser is directed onto the surface of a material being tested. When any deformation occurs on the surface, a corresponding change in the light pattern is produced. This change is analyzed using specialized equipment that interprets the interference patterns generated.

Technicians can identify issues that are not visible to the naked eye. The sensitivity of this technology can detect minute defects that may lead to catastrophic failures if left undetected. The entire process is non-invasive, which means that the integrity of the material is preserved during testing.

Principles and Applications of Shearography

Shearography employs laser interferometry to identify variations in material surfaces. This process detects strain levels that propagate through materials so that inspectors can observe minute defects that technology might otherwise overlook. The primary benefit of shearography lies in its capacity to reveal delaminations, cracks, or weak points in composite and bonded structures.

The technology creates a fringe pattern that highlights areas of concern, enabling immediate and accurate assessments. Its non-contact nature means there’s no need for elaborate surface preparations, simplifying the inspection process. Industries are adopting shearography NDT due to its effectiveness across multiple materials, from metals to composites. Manufacturing sectors can optimize their quality control processes and reduce the risk associated with structural failures.

The Advantages of Shearography in Non-Destructive Testing

The adoption of shearography in non-destructive testing offers numerous advantages that set it apart from traditional methods. The technique’s speed enables rapid inspections, saving valuable time in production cycles. Shearography can analyze large areas in a fraction of the time it takes more conventional inspection technologies. Its ability to visualize subsurface defects improves quality assurance and mitigates the need for extensive destructive testing.

By identifying issues early in the manufacturing process, companies can prevent costly recalls or rework. The portable nature of shearography equipment allows for on-site inspections, reducing logistical challenges and streamlining operations.

Challenges and Future of Shearography Technology

Shearography faces certain challenges that affect its widespread implementation. The primary concern is the operator skill level: accurate interpretation of shearography results requires specific training and experience. The technology is remarkably effective for many applications, but certain complex geometries or composite structures may present difficulties in obtaining precise measurements.

To tackle these issues, ongoing development and updates in technology are necessary. With artificial intelligence algorithms for data analysis and improved laser systems, there is great potential for shearography to become even more efficient and user-friendly. The integration of machine learning capabilities can assist in the identification of defects with greater accuracy and speed. The outlook for shearography remains promising, positioning it as a central player in the future of non-destructive testing methodologies.

Shearography represents a remarkable evolution in non-destructive testing techniques, offering unparalleled benefits to multiple industries. With its precision in identifying subsurface defects and its efficiency in inspections, this technology is building a safer and more reliable future for engineering and manufacturing. The full potential of shearography will likely reshape quality assurance practices across the board.